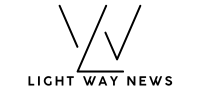

The SC70_5_65p package is a popular surface-mount technology (SMT) component widely used in modern electronics. This package is known for its compact size, high reliability, and versatility, making it an ideal choice for applications requiring miniaturization and precision. In this guide, we will explore every aspect of the SC70_5_65p, from technical specifications to design considerations, ensuring you have a comprehensive understanding of its features and applications.

Technical Specifications of SC70_5_65p

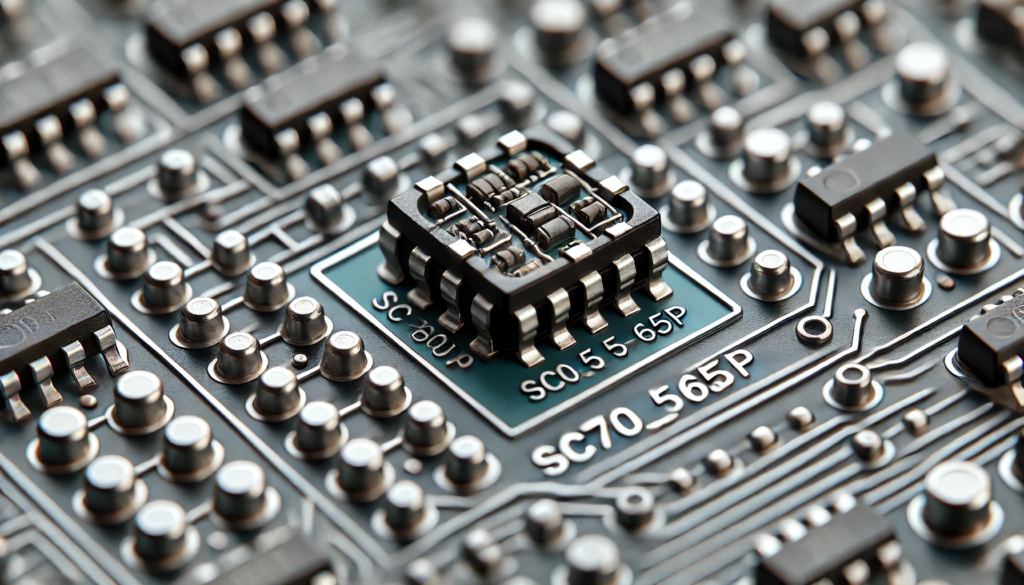

The SC70_5_65p package offers a range of specifications that make it suitable for advanced electronic designs. Here is a summary of its key attributes:

| Specification | Details |

| Package Type | SC70 |

| Number of Pins | 5 |

| Pin Pitch | 0.65 mm |

| Body Dimensions | 2.0 mm x 1.25 mm |

| Material | Plastic Mold Compound |

| Thermal Resistance | Low for efficient cooling |

| Maximum Operating Voltage | Typically 20V – 40V |

| Operating Temperature Range | -40°C to 125°C |

The small footprint and low profile of SC70_5_65p make it ideal for portable and space-constrained devices. Its robust material composition ensures durability under various environmental conditions.

Applications of SC70_5_65p

Common Uses

The SC70_5_65p package is employed in a diverse range of electronic devices. Its small size and excellent electrical characteristics make it indispensable for:

- Portable Electronics: Smartphones, wearable devices, and tablets frequently use SC70_5_65p components due to their compact design.

- Communication Systems: The package is common in RF circuits, signal amplifiers, and filters.

- Power Management: Integrated circuits for voltage regulation often use SC70_5_65p packaging.

- Automotive Electronics: Modern vehicles rely on SC70_5_65p components for sensors and control modules.

Industries Benefiting from SC70_5_65p

- Consumer Electronics

- Automotive Manufacturing

- Telecommunications

- Industrial Automation

Design Considerations for SC70_5_65p

PCB Layout Guidelines

When designing printed circuit boards (PCBs) for SC70_5_65p components, careful consideration must be given to the following factors:

- Solder Pad Dimensions: Ensure precise pad dimensions to avoid solder bridging.

- Thermal Vias: Incorporate vias near the component for better heat dissipation.

- Trace Width: Maintain appropriate trace widths to handle current without overheating.

Thermal Management

Heat can be a limiting factor in SC70_5_65p performance. Use the following strategies:

- Heatsinks: Attach small heatsinks if space allows.

- Thermal Pads: Use conductive thermal pads to enhance heat transfer.

- Airflow Optimization: Design enclosures to facilitate airflow around the component.

Manufacturing and Assembly of SC70_5_65p

The SC70_5_65p package is designed for automated assembly processes, ensuring high accuracy and efficiency.

Surface-Mount Technology (SMT) Compatibility

- Pick-and-Place Machines: SC70_5_65p components are compatible with most modern pick-and-place systems due to their standardized size and weight.

- Reflow Soldering: A precise reflow profile ensures reliable soldering without damage to the component.

Inspection and Quality Control

- X-ray Inspection: Used to detect soldering defects, such as voids and misalignments.

- Electrical Testing: Verifies functionality post-assembly.

Reliability and Testing of SC70_5_65p

To ensure optimal performance, SC70_5_65p components undergo rigorous testing:

- Thermal Cycling: Tests resilience to temperature variations.

- Humidity Resistance: Assesses performance in high-moisture environments.

- Electrical Load Testing: Ensures consistent operation under varying loads.

Case Studies

Example 1: Use in Wearable Technology

A leading manufacturer of fitness trackers integrated SC70_5_65p components into their design, achieving a 20% reduction in size while maintaining performance.

Example 2: Automotive Sensor Applications

SC70_5_65p was utilized in temperature sensors for electric vehicles, providing reliable data under extreme conditions.

Future Trends for SC70_5_65p

The demand for smaller, more efficient components is driving innovation in SC70_5_65p technology. Future trends include:

- Integration with AI Circuits: Optimizing for machine learning applications.

- Advanced Materials: Enhancing thermal and electrical performance.

- Wider Adoption in IoT Devices: Enabling smarter connectivity solutions.

FAQ’s

1. What is the SC70_5_65p package used for?

The SC70_5_65p is used in portable electronics, automotive systems, and communication devices due to its compact size and reliable performance.

2. How does SC70_5_65p differ from SOT-23?

SC70_5_65p is smaller and has a narrower pin pitch, making it suitable for miniaturized applications compared to SOT-23.

3. What are the thermal management options for SC70_5_65p?

Options include using thermal vias, heatsinks, and optimized airflow in the design.

4. Is SC70_5_65p suitable for high-frequency circuits?

Yes, its design minimizes parasitic capacitance and inductance, making it ideal for high-frequency applications.

5. What is the pin configuration of SC70_5_65p?

SC70_5_65p typically has five pins with a standard pitch of 0.65 mm.

6. What precautions should be taken during the handling of SC70_5_65p components?

SC70_5_65p components are sensitive to static electricity and mechanical stress. Use ESD-safe tools and handling practices to prevent damage. Ensure proper storage in anti-static packaging to avoid contamination or damage during transit.

7. Can SC70_5_65p be used in high-power applications?

SC70_5_65p is generally suited for low-power applications due to its small size and thermal dissipation capabilities. For higher power requirements, consider using packages specifically designed for robust thermal management.

8. How does the SC70_5_65p package contribute to environmental sustainability?

The small size and lightweight design of SC70_5_65p reduce material usage and energy consumption during manufacturing. Additionally, many components in this package comply with RoHS and other environmental standards, minimizing hazardous substances.

9. What testing standards ensure the reliability of SC70_5_65p components?

SC70_5_65p components are tested against industry standards such as JEDEC for thermal performance, IEC for environmental resilience, and IPC for assembly and soldering quality. These standards ensure their reliability in various applications.

10. Are there any alternatives to SC70_5_65p for ultra-compact designs?

Alternatives include packages like DFN (Dual Flat No-Lead) and CSP (Chip-Scale Package), which also cater to compact and high-density designs. The choice depends on the application\u2019s electrical and mechanical requirements.

Conclusion

The SC70_5_65p package is a versatile and reliable solution for modern electronics, offering compact size and excellent performance across various applications. By understanding its specifications, design considerations, and future trends, engineers and designers can leverage this package to create innovative and efficient products. With proper implementation and optimization, the SC70_5_65p continues to play a crucial role in advancing technology.

Recommand Article:

12V LED High Lumen Light Ceiling: The Ultimate Guide

Let the Good into the Mirror of Korean Photography Notes (ISBN: 7122192912)

Toaster Bath Bomb: The Ultimate Guide to a Fun and Relaxing Experience!

The Ultimate Guide To The Zyn Rewards List – Maximize Your Points!

Husqvarna 517203204 – A Comprehensive Guide to Performance and Longevity!