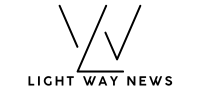

In the world of 3D printing, precision and durability are key. The “bearing_shield_petg_v9.2_small_big” is a specially designed component aimed at enhancing performance and longevity in various 3D printing setups. This guide provides a comprehensive overview of its features, benefits, and applications to ensure you have all the information you need to make the most of this innovation.

What Are Bearing Shields?

Bearing shields are essential components that protect bearings from dust, debris, and contaminants, ensuring smooth and efficient operation. They act as a barrier, reducing wear and extending the lifespan of your 3D printer or other machinery.

Types of Bearing Shields

- Contact Shields: Provide a tight seal to prevent contaminants but may increase friction.

- Non-Contact Shields: Allow for less friction but offer slightly less protection.

The “bearing_shield_petg_v9.2_small_big” falls under the non-contact category, balancing efficiency with protection.

Why Choose PETG?

Polyethylene Terephthalate Glycol-modified (PETG) is a popular material for 3D printing due to its durability, flexibility, and resistance to environmental factors. Let’s dive deeper into why PETG is the ideal choice for this bearing shield.

Advantages of PETG

- Durability: PETG withstands mechanical stress, making it perfect for components subjected to constant motion.

- Heat Resistance: It can handle higher temperatures compared to PLA.

- Low Warping: Ensures accurate and reliable prints.

- Chemical Resistance: Ideal for environments exposed to oils or other chemicals.

| Property | PETG | PLA | ABS |

| Strength | High | Moderate | High |

| Heat Resistance | Moderate | Low | High |

| Ease of Printing | Moderate | High | Low |

| Flexibility | High | Low | Moderate |

Updates in Version 9.2

The “bearing_shield_petg_v9.2_small_big” has seen significant upgrades from previous iterations. Key improvements include:

- Enhanced Fit: Improved tolerances ensure compatibility with a broader range of printer models.

- Reinforced Structure: Increased durability to handle prolonged use.

- Optimized Dimensions: Available in both small and big sizes to cater to different setups.

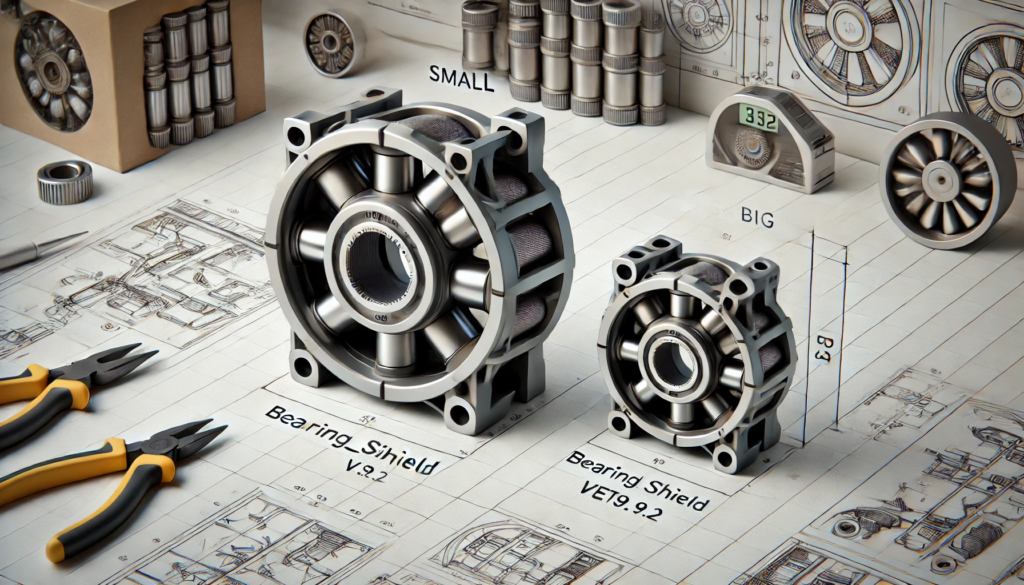

Size Variations: Small vs. Big

The product comes in two main size variations, catering to different needs:

Small Version:

- Suitable for compact 3D printers.

- Lightweight and easy to install.

Big Version:

- Designed for larger printers or applications requiring additional protection.

- Provides enhanced stability.

Table of Dimensions

| Version | Diameter (mm) | Thickness (mm) |

| Small | 25 | 5 |

| Big | 50 | 8 |

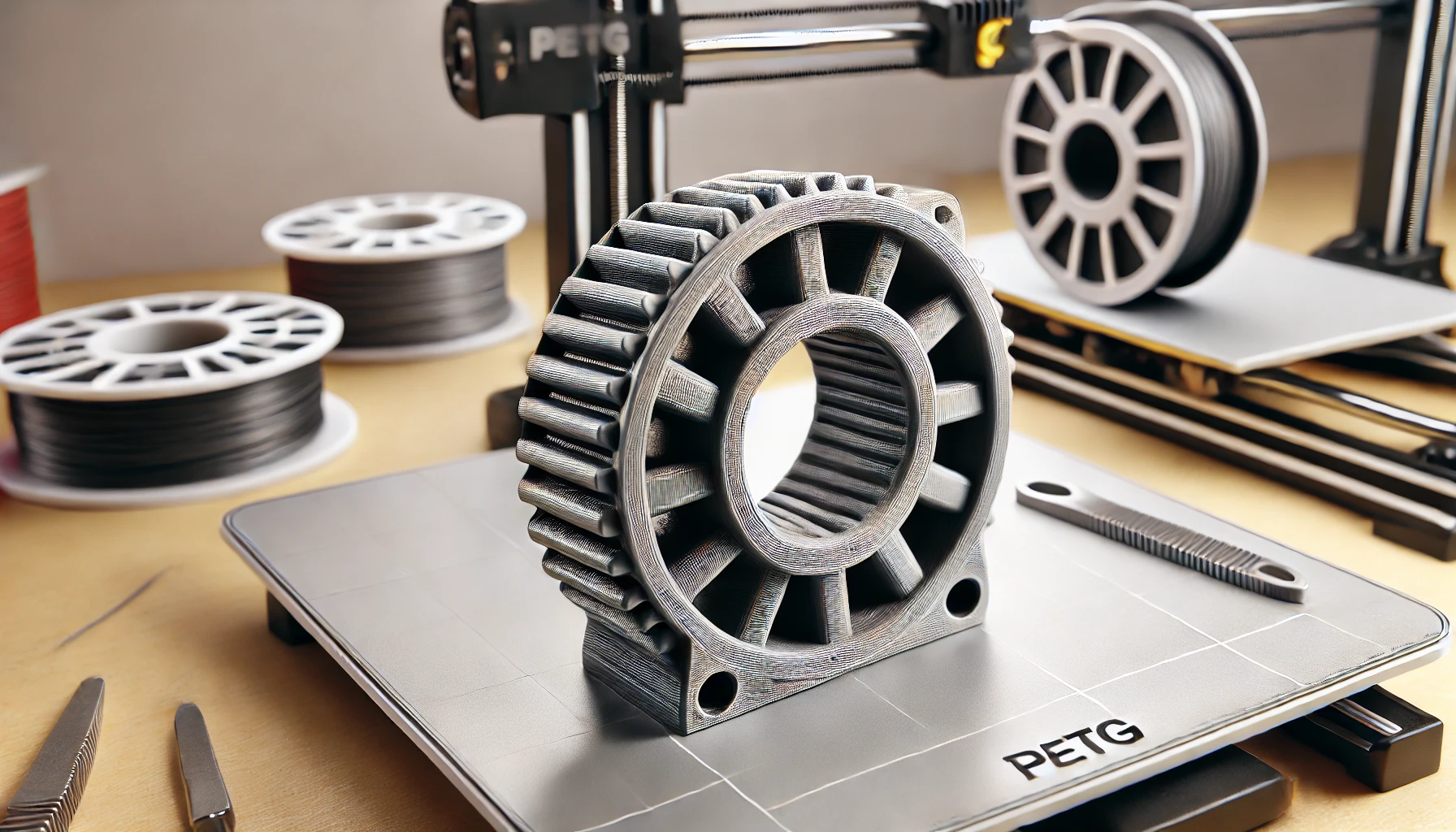

Printing Guidelines

For optimal results, follow these printing settings:

- Layer Height: 0.2 mm for a balance between detail and speed.

- Infill Density: 40% to 60% for strength.

- Print Speed: 40–60 mm/s.

- Bed Temperature: 70–80°C to prevent warping.

- Extruder Temperature: 230–250°C for proper adhesion.

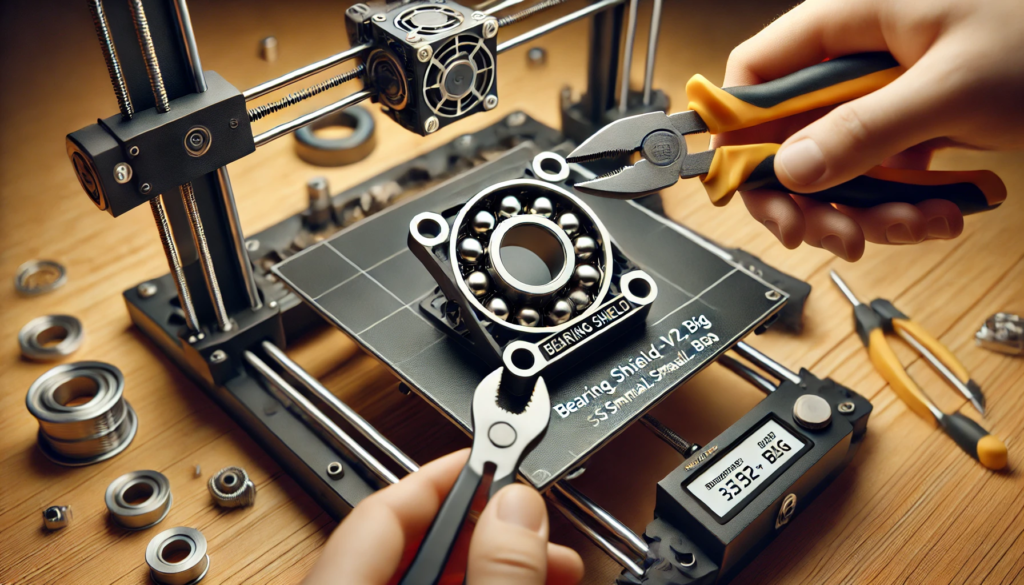

Installation Instructions

Installing the “bearing_shield_petg_v9.2_small_big” is straightforward:

- Prepare Tools: Ensure you have a hex wrench and cleaning cloth ready.

- Remove Old Shield: Carefully detach the old bearing shield if present.

- Clean the Bearing Area: Use a lint-free cloth to remove dust and debris.

- Install the New Shield: Align the “bearing_shield_petg_v9.2_small_big” with the bearing and secure it in place using the provided screws.

Maintenance and Troubleshooting

Maintenance Tips

- Regular Cleaning: Wipe down the shield monthly to remove buildup.

- Lubrication: Apply lubricant to the bearing for smoother operation.

- Check for Damage: Inspect for cracks or wear and replace if necessary.

Common Issues and Fixes

- Fitment Problems: Sand the edges lightly for a snug fit.

- Warping: Ensure the print bed is level and at the correct temperature.

- Layer Separation: Increase the extruder temperature slightly.

FAQ’s

1. Can I Use The “Bearing_shield_petg_v9.2_small_big” With Any 3d Printer?

It is compatible with most standard 3D printers but check dimensions for specific fitment.

2. Is Petg Suitable For Outdoor Use?

Yes, PETG is UV and weather-resistant, making it ideal for outdoor applications.

3. How Long Does It Take To Print?

Printing time varies based on size; the small version takes approximately 2 hours, while the big version takes around 4 hours.

4. Can I Modify The Stl File?

Yes, the file is modifiable for custom applications.

5. What Is The Lifespan Of This Bearing Shield?

With proper care, it can last several years under normal usage conditions.

6. What Are The Key Differences Between Petg And Other Materials For Bearing Shields?

A detailed comparison of PETG, PLA, and ABS in terms of performance, durability, and suitability for specific use cases.

7. How Do I Customize The “Bearing_shield_petg_v9.2_small_big” Design For My Printer?

Steps or tools required to modify the STL file for custom applications.

8. What Are The Signs Of A Poorly Performing Bearing Shield?

Common indicators like unusual noise, reduced smoothness, or visible wear.

9. Can The “Bearing_shield_petg_v9.2_small_big” Be Used In Industrial Applications?

Discussion on its suitability and limitations for non-3D printing uses.

10. What Troubleshooting Steps Can I Take If My Bearing Shield Doesn’t Fit Correctly?

Detailed solutions like reprinting with adjusted settings or minor modifications to the shield.

Conclusion

The “bearing_shield_petg_v9.2_small_big” is a reliable and versatile component for enhancing your 3D printing setup. With its robust PETG construction, thoughtful design, and ease of use, it’s a valuable addition to any enthusiast’s toolkit. By following this guide, you’ll be well-equipped to maximize its benefits and ensure your 3D printer operates at peak performance.

Recommand Article:

The Comprehensive Guide to the CFMoto 4060-050101 Front Arm Shaft!

12V LED High Lumen Light Ceiling: The Ultimate Guide

Let the Good into the Mirror of Korean Photography Notes (ISBN: 7122192912)

Toaster Bath Bomb: The Ultimate Guide to a Fun and Relaxing Experience!

Everything You Need to Know About 48V 150Ah 7.68kWh Lithium Battery LiFePO4