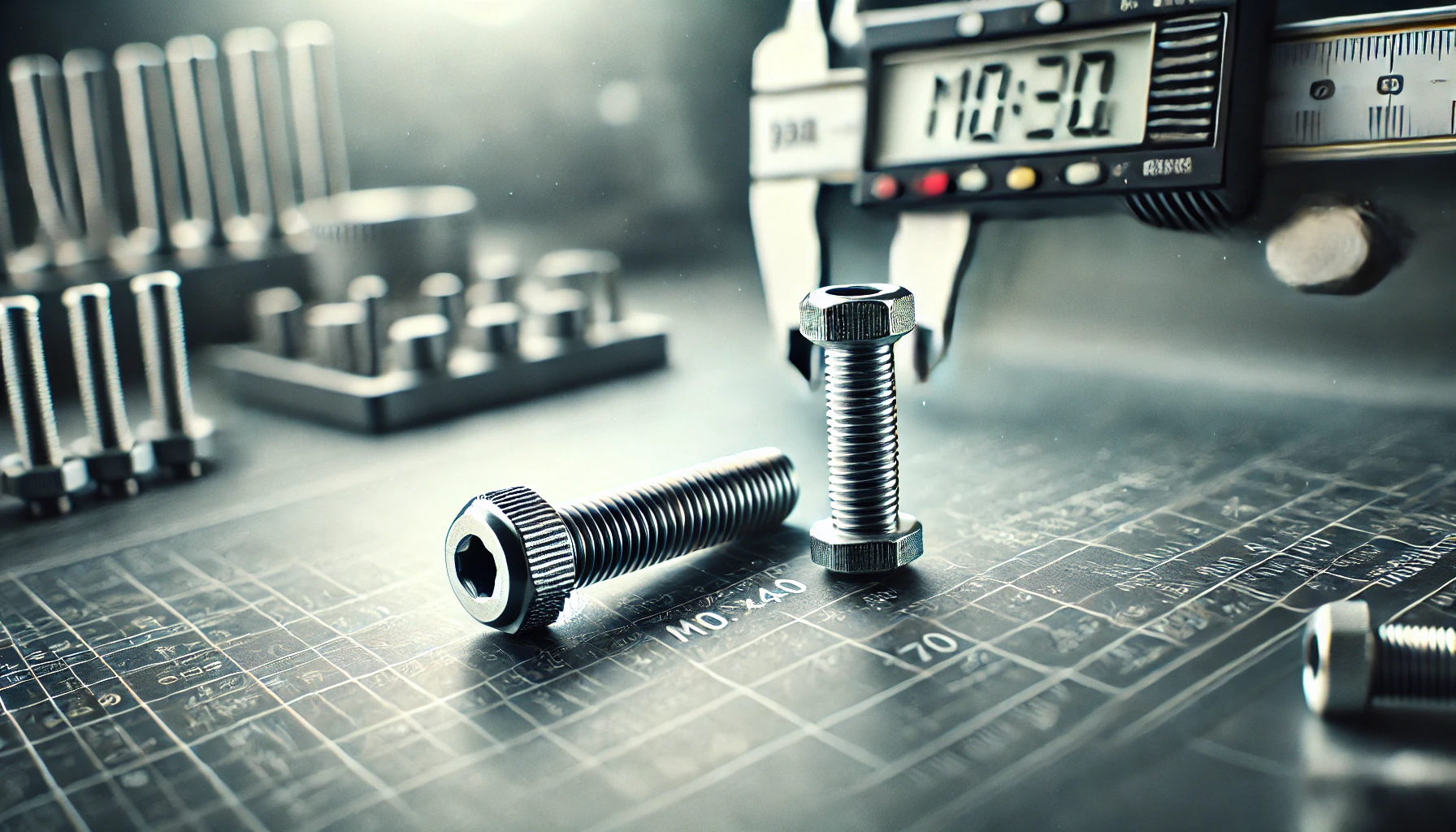

When it comes to precision engineering and industrial components, the DIN 938 – M10x40 – A2-70-L2A Elesa part stands out as a reliable and high-quality choice. This guide delves deep into every aspect of this component, from understanding its specifications to exploring its applications, installation methods, and much more. Let’s uncover why this fastener is a preferred choice in various industries.

Understanding DIN 938 Standard

What is DIN 938?

The DIN 938 standard specifies double-ended stud bolts commonly used in mechanical engineering and construction applications. These bolts feature threads on both ends, one longer than the other, allowing them to be securely fastened to different materials or components. Their design ensures a robust and permanent connection.

Why Choose DIN 938?

The DIN 938 standard ensures consistency, precision, and reliability. Components adhering to this standard are designed to meet rigorous mechanical and dimensional requirements, making them suitable for high-stress applications.

Comparison with Other DIN Standards

While DIN 938 focuses on double-ended stud bolts, other standards like DIN 931 and DIN 939 cater to different bolt designs. DIN 938 is preferred where threaded connections need to accommodate diverse materials and configurations.

Specifications of M10x40

Thread Dimensions and Tolerances

The M10x40 indicates:

- M10: Metric thread with a nominal diameter of 10 mm.

- 40: Overall length of the bolt, measured in millimeters.

The threads conform to ISO metric profiles, ensuring compatibility with standard nuts and tapped holes.

Length Specifications

The length is distributed to provide adequate grip and engagement on both ends. Precise measurement ensures proper fitting and structural stability.

Load Capacity

These bolts, made from A2-70 stainless steel, offer excellent tensile strength, with a minimum breaking load of 700 MPa. This makes them suitable for demanding applications.

Material Analysis: A2-70 Stainless Steel

Chemical Composition

A2-70 stainless steel is composed of:

- Chromium: Ensures corrosion resistance.

- Nickel: Enhances ductility and toughness.

- Carbon: Adds strength.

Mechanical Properties

This grade of stainless steel offers:

- High tensile strength.

- Excellent resistance to wear and tear.

- Durability in extreme conditions.

Corrosion Resistance

The alloy’s resistance to rust makes it ideal for outdoor, marine, and chemical exposure applications.

Manufacturer Spotlight: Elesa

Overview of Elesa

Elesa is a globally recognized manufacturer of industrial components, renowned for its innovative designs and high-quality materials. With decades of experience, Elesa products are trusted by engineers worldwide.

Quality Assurance

Elesa adheres to strict quality control measures, ensuring every product meets international standards. Certifications like ISO 9001 underscore their commitment to excellence.

Applications of DIN 938 M10x40 A2-70 Components

Industries Benefiting from This Component

- Industrial Machinery: Used in the assembly of heavy-duty equipment.

- Construction: Essential for structural connections.

- Automotive Sector: Found in engine and chassis assembly.

- Marine Applications: Resistant to saltwater corrosion, ideal for shipbuilding.

Case Study: Marine Application

In a recent project, these bolts were used in the assembly of a coastal wind turbine. Their corrosion resistance and tensile strength ensured long-term reliability.

Installation and Maintenance

Installation Guidelines

- Use appropriate tools like a torque wrench.

- Ensure threads are clean and free of debris.

- Tighten to specified torque values to avoid overloading.

Maintenance Tips

- Regularly inspect for signs of wear or corrosion.

- Apply anti-seize compounds in high-humidity environments.

Purchasing Considerations

Verifying Authenticity

- Look for Elesa branding on the packaging.

- Check for a proper product code and certification.

Authorized Dealers

Purchase from trusted suppliers or Elesa’s official website to ensure authenticity.

FAQ’s

1. What Is The Tensile Strength Of A2-70 Stainless Steel?

A2-70 stainless steel has a tensile strength of 700 MPa, making it suitable for high-stress applications.

2. Can These Bolts Be Used In Extreme Temperatures?

Yes, A2-70 bolts perform well in a wide range of temperatures, but for extreme heat, specialized grades may be required.

3. Are Din 938 Bolts Reusable?

Reusability depends on the application and wear. Inspect threads before reuse.

4. What Tools Are Best For Installing Din 938 Bolts?

A torque wrench ensures accurate tightening and prevents overloading.

5. Where Can I Buy Authentic Din 938 Bolts?

Elesa’s official website and authorized dealers are the best sources.

6. What does the “L2A” designation signify in DIN 938 – M10x40 – A2-70-L2A Elesa?

The “L2A” designation often refers to a specific surface treatment, finish, or design odification unique to the manufacturer, Elesa. It ensures compatibility and performance for specialized applications. Always check the manufacturer’s documentation for exact details.

7. How does DIN 938 differ from DIN 939 in stud bolt design?

While both standards deal with stud bolts, DIN 938 specifies double-ended studs with unequal thread lengths, whereas DIN 939 focuses on studs with equal thread lengths. This makes DIN 938 more suitable for applications requiring specific engagement depths.

8. Can these bolts be customized for unique industrial applications?

Yes, manufacturers like Elesa often offer customization options, including unique lengths, coatings, or materials, to meet specific project requirements. Contact Elesa directly for tailored solutions.

9. What are the environmental limitations of A2-70 stainless steel?

A2-70 stainless steel performs well in standard industrial and marine environments, but it is not suitable for highly acidic or chloride-rich conditions, where grades like A4 stainless steel might be preferred.

10. What are the common issues encountered during the installation of DIN 938 bolts?

Common issues include improper thread alignment, over-tightening leading to thread stripping, and failure to clean threads before installation. Using appropriate tools and following the manufacturer’s guidelines can mitigate these problems.

Conclusion:

The DIN 938 – M10x40 – A2-70-L2A Elesa bolt is a versatile and reliable component, ideal for various industrial applications. With its adherence to international standards, excellent material properties, and Elesa’s trusted quality, this component is a top choice for engineers and manufacturers. By understanding its specifications, applications, and installation methods, you can ensure optimal performance and longevity in your projects.

Recommand Article:

Comprehensive Guide To Bunkralbum – Your Ultimate Digital Music Companion!

Aida Dzubur Cleaning Chicago – Your Trusted Partner for a Spotless Space!

The Ultimate Guide to the Kohler Air Filter DH24005683!

The Ultimate Guide to SC70_5_65p – Comprehensive and In-Depth!

Baimoqi Car Digital Clock Manual – The Ultimate Guide For Setup And Maintenance!