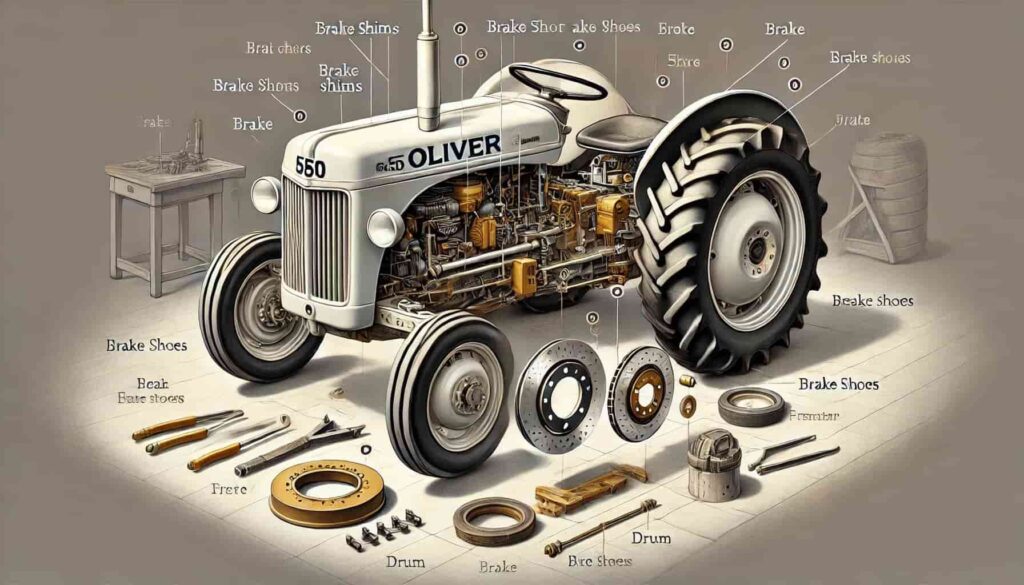

Rear brake shims play a critical role in the braking system of the 550 Oliver tractor, ensuring proper alignment and efficient braking. This guide dives deep into their functionality, adjustment techniques, maintenance practices, and common troubleshooting steps. Whether you’re a seasoned tractor owner or a beginner, this detailed resource will equip you with the knowledge to keep your Oliver 550 operating safely and smoothly.

What Are Rear Brake Shims?

Rear brake shims are thin metal plates located in the braking assembly of the 550 Oliver tractor. They are designed to adjust the spacing between the brake shoes and the drum, ensuring optimal alignment and functionality. This alignment prevents excessive wear on brake components, enhances safety, and ensures the longevity of the braking system.

Importance Of Rear Brake Shims

Properly adjusted rear brake shims are essential for several reasons:

- Efficient Braking: They ensure smooth engagement of the brake shoes with the drum, preventing issues like spongy or ineffective brakes.

- Even Wear: With proper alignment, the brake shoes wear evenly, reducing the need for frequent replacements.

- Enhanced Safety: Correctly adjusted shims maintain reliable braking, critical during heavy loads or steep inclines.

Signs You Need To Adjust Or Replace Rear Brake Shims

Understanding when to inspect and adjust your rear brake shims can save you time and money. Common signs include:

- Reduced braking efficiency, such as longer stopping distances.

- Uneven wear on brake shoes or drums.

- Unusual noises like grinding or squealing during braking.

If you notice any of these symptoms, it’s time to inspect the shims and consider adjustments or replacements.

How To Adjust Rear Brake Shims On A 550 Oliver Tractor

Tools Needed

To adjust the rear brake shims, gather the following tools:

- Wrenches and screwdrivers

- Jack and jack stands

- Safety gear, including gloves and goggles

Step-by-Step Guide

- Preparation: Park the tractor on a level surface, engage the handbrake, and disconnect the battery. Use a jack to lift the rear end and secure it with jack stands.

- Access the Brakes: Remove the rear wheels to expose the brake assembly. Locate the shims between the brake shoes and the backing plate.

- Inspect the Shims: Check the condition of the shims. If they’re worn, bent, or damaged, replace them with new ones.

- Adjust the Spacing: Add or remove shims as needed to achieve proper spacing between the brake shoes and drum. Refer to the service manual for the exact clearance specifications.

- Reassemble and Test: Reinstall the wheels, reconnect the battery, and test the brakes at a low speed to ensure optimal function.

Maintenance Tips For Rear Brake Shims

To extend the life of your rear brake shims and maintain optimal performance:

- Inspect the shims during regular maintenance checks, ideally every 100 operating hours.

- Clean the brake assembly to prevent dirt and debris from affecting the shim’s alignment.

- Use high-quality OEM shims for replacements to ensure compatibility and durability.

Common Issues And Troubleshooting

Issue 1: Brake Drag

If the brakes feel like they’re dragging, it may be due to excessive shim thickness. Remove a shim or two and test the brakes again.

Issue 2: Uneven Braking

This often results from improper shim placement or damage. Inspect and reposition the shims to correct the issue.

Issue 3: Spongy Brakes

Insufficient shim thickness can lead to spongy brakes. Add shims incrementally until the correct clearance is achieved.

Safety Precautions

While adjusting rear brake shims, prioritize safety:

- Wear gloves and safety glasses to protect against debris.

- Always use a jack and stands rated for the weight of your tractor.

- Refer to the Oliver 550 service manual for specific guidelines and torque specifications.

Frequently Asked Questions (FAQs)

1. How Often Should I Check The Rear Brake Shims?

Inspect the shims during every routine maintenance session, typically every 100 operating hours.

2. Can I Use Universal Shims For The Oliver 550?

While universal shims might fit, it’s recommended to use OEM parts for the best compatibility and performance.

3. What Happens If I Don’t Adjust The Shims?

Ignoring shim adjustments can lead to uneven brake wear, reduced braking efficiency, and potential safety hazards.

4. Is It Difficult To Adjust Brake Shims?

With the right tools and guidance, adjusting brake shims is straightforward. Follow this guide or consult a professional if unsure.

5. Are Brake Shims Reusable?

Shims can be reused if they are in good condition. Replace them if they are bent, cracked, or excessively worn.

6. Can Rear Brake Shims Affect The Tractor’s Alignment Or Overall Performance?

Yes, improperly adjusted or damaged rear brake shims can cause uneven braking, which might affect the tractor’s stability, especially during heavy loads or when operating on uneven terrain.

7. What Materials Are Rear Brake Shims Typically Made From, And Do They Impact Durability?

Rear brake shims are usually made of durable metals such as stainless steel or brass. The material ensures longevity and resistance to wear, but selecting the right type based on your tractor’s specifications is crucial.

8. Do I Need To Replace The Brake Drum If The Shims Are Damaged?

Not necessarily. If the brake drum shows no signs of damage or excessive wear, you can replace just the shims. However, it’s a good idea to inspect the entire braking system when servicing the shims.

9. What Are The Symptoms Of Warped Or Misaligned Brake Drums, And Can Shims Fix This Issue?

Symptoms include vibration, uneven braking, or unusual noises when applying the brakes. Shims alone cannot fix warped drums; in such cases, the brake drums need to be repaired or replaced.

10. Can Adding Too Many Shims Damage Other Brake Components?

Yes, excessive shim thickness can lead to excessive brake shoe pressure on the drum, causing premature wear of both the shoes and the drum. This can also overheat the braking system, reducing its efficiency.

Conclusion:

Rear brake shims on the 550 Oliver tractor are small yet vital components for maintaining an efficient and reliable braking system. Regular inspections, proper adjustments, and timely replacements can significantly enhance your tractor’s performance and longevity. By following this guide, you can ensure that your Oliver 550 operates safely and smoothly for years to come.